Locomotives -

Operational Locos -

Locos under overhaul -

Locos on static display -

Locos formerly based on the Bluebell

Loco Roster -

Loco Stock List -

Loco Works News -

Join the Loco Dept

Atlantic Project - Background - Completion and launch - Next Projects: 'Normandy' and the Adams Radial Tank

Bluebell Railway Atlantic Group

2011 progress

14 January 2011

A short report, again illustrated by Fred Bailey's photos, showing deliveries of some rather useful bits for the loco.

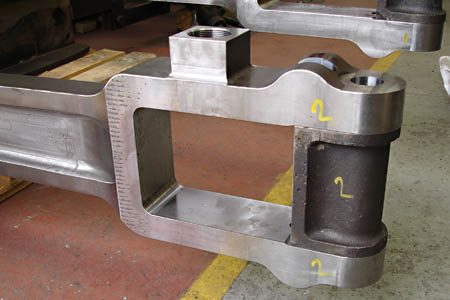

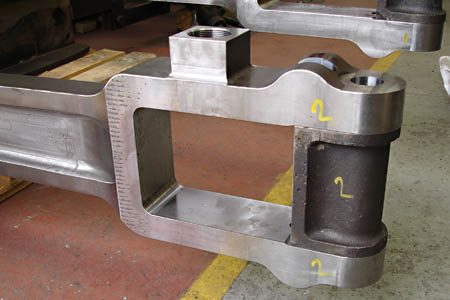

On the right and below we see the newly arrived coupling rods, which have been machined, and three of the four main axleboxes, which are now with us (the fourth to follow shortly).

Also finished, but not photographed is the main body for the reverser and the four sand boxes. Patterns are completed for the valve heads, cylinder relief valves (2 types), the drain cocks and the brake blocks.

The lever for the reverser in the cab is complete, and in order to be able to assemble these, we have one cab side and all the relevant parts to make up the stand, in stock awaiting riveting.

The final two photos show that, now the sealing arrangements for the steam chest to cylinder have been finalised, the holes though the frames have been cut to suit, and that the rear cylinder covers have now arrived.

We hope this gives all of our supporters enough encouragement to realise that we are still moving forward as fast as we are able. Should anyone wish to provide further fiancial assistance, it will be most welcome, since continued progress is reliant on a continuous income!

1 June 2011

The next project open days are June 25-26, with Atlantic House at Sheffield Park open for viewing between 10am and 5pm. On the Sunday the session restricted to project supporters, friends and subscribers, with special guest Richard Gibbon, will be between 1.15 and 3.30pm (ceremony at 2.30), followed by an auction, the principal attraction of which is an original painting by G.F.Watts of an LMS Garrett locomotive (reserve £150 - commission bids accepted). For further information contact David Jones.

Richard Gibbon does Coast to Coast Walk to help the Atlantic project.

On June 11-12 Richard is doing the first 65 miles of his Coast to Coast walk, from St.Bees to Shap, with sponsorship going to our project. Will you help us by sponsoring him per mile or for the complete journey? Please e-mail your pledge to David Jones/Atlantic Project.

Another progress report follows, with thanks to Fred Bailey for most of the photos and the descriptions.

On the right is a photo taken by Neville Watts at the South Devon Railway of one of our driving wheelsets. They await the drilling, boring and quartering of the crankpin holes and final turning of the tyres. The driving wheelsets should be entering their works very shortly. Once this work has been done, they return to Riley's in Lancashire for the crankpin fitting before delivery back to us. If you ignore the tyres coming from South Africa, the wheelsets will probably have done more miles up and down the country before being fitted to the engine than they will in the frst five years of service on the Bluebell!

The next photo shows some work in progress, the fabricated smoke-box saddle, which is sitting up on its end. The general view shows the two connecting rods and the final main axlebox, at long last received from the machine shop in the Midlands.

The final two are more detailed views of the small end and big end on the connecting rods. The stripes on the side of the small end are remnants of the packing from between the two rods. All in all they look like a nice job, probably a bit better finished than we expected. We still have to fettle them up before they are ready for fitting to the engine.

The component sponsorship list has been updated with some more parts now available for sponsorship.

August 2011

The first photo, from Fred Bailey, shows the valve chest in the frames with the smokebox saddle in position, for its first trial fitting after coming from the Kearns borer in the main works.

The next photo shows the reaming of the holes that take the bolts that hold the valve chest in position, the unit having previously been aligned to the centre of the driving axle. All this drilling is again done using the mag-based drill. Note the machined surface of the valve chest against which the seals will bear.

The next three photos show progress with the reverser mechanism. That on the right shows the completion of the first stage of machining the reverser handle.

The next three photos show progress with the reverser mechanism. That on the right shows the completion of the first stage of machining the reverser handle.

Below we see the drilling of the oiling hole in the reverser index plate - all done in house on the Dufor mill.

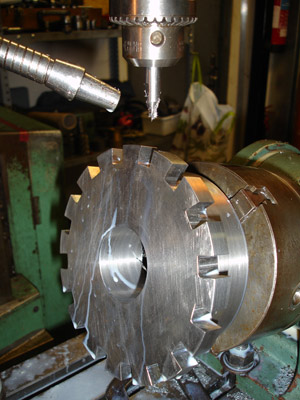

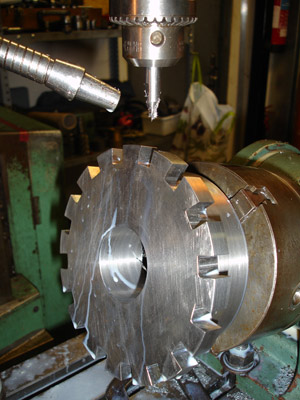

The spherical turning attachment was specially made by the team, and is seen being used to form the handles for the cab reverser.

The reverser handle is now nearing completion and a photo or two of the finished assembly should follow shortly.

The cylinder and valve liners are nearing completion at our sub-contractor's works in Birmingham, while progress is also being made in Atlantic House on the final adjustments to the axleboxes as well as with the cylinder pressure relief valves.

This photo shows the bodies part machined for the front (long) and rear (short) cylinder relief valves.

These last two photos show the first of the axleboxes, with the manganese steel liners welded on and the oil tray in position.

September 2011

The first set of photos shows Fred Bailey's work on the reverser. On the right we see the handles; the top one has a sprung detent inside the handle so that it stays engaged with or disengaged from the catch plate behind it.

Below we see the cab reverser wound full forward, and then in full reverse position. The vertical arm is seen in reverse gear position; the smaller vertical arm does the same job but for the drain cocks.

Below is a photo of two of the valve head castings; there are 8 in all to suit the semi-plug valves.

The final photo shows the patterns and core boxes for the crossheads, the latest of many intricate patterns made for casting components for the project.

More recent news updates

- 2012 - Valve and cylinder liners fitted - lifting and reversing arms and axlebox crowns delivered - castings for mudhole doors, regulator and whistle valves, reversing shaft clutch, blast-pipe cap, crosshead slippers, 'J' pipe and eight eccentric halves received - Bogie and trailing axle now support the frames - Valve chest and cylinders fitted to frames, covers fitted, and pressure tested.

- 2013 - Cylinders, valves, slidebars and crossheads completed - driving wheels completed - valve gear components delivered - lifting frames constructed.

- 2014 - Weigh (reversing) shaft and air-clutch fitted, axleboxes metalled, machined and fitted, wheel rotators constructed, eccentric rods, valve and reversing gear, pipework for brakes and steam heat completed, locomotive wheeled, cylinders clad and crossheads fitted.

- 2015 - Rolling Chassis completed with all motion erected. Running plates and splashers completed, along with cab sides and front.

- 2016 - Connecting and coupling rods fitted, valves set. Superheater header delivered. Revision of boiler internal pipework completed. Cab roof riveted together and fitted. Mud-hole patches welded into boiler. Flue tubes (with screw ends welded on) delivered.

- 2017 - Major progress on the boiler overhaul, and with the safety valves.

- 2018 - Boiler tubes fitted, tender made mobile, complex parts of the boiler cladding made.

- Most recent news.

Older news updates

- Background and early progress

- September 2001: Repairs to tender chassis.

- More photos of the project (1999-2002).

- March 2002: Modification of front end of tender.

- November 2004: Loco Frames ordered.

- December 2004: Bogie frame components arrive - also Feb.2005 news report.

- 2005 - Loco main frames arrive - tender frames nearly completed - start of construction of the shed.

- 2006 - Loco driving wheel castings delivered - drilling of the main frames and hornguides - building of the shed completed.

- 2007 - Main locomotive frames erected.

- 2008 - Components for the cylinders and valve chest delivered - frames riveted - forged billets for connecting and coupling rods delivered.

- 2009 - First motion parts water-jet cut from forged blanks - bogie frames assembled.

- 2010 - Cylinders and valve chests fabricated, air brake cylinders completed, bogie and trailing wheelsets completed.

Project Funding

A fund raising appeal for the cash required to complete the project was launched in 2000, and a combination of gifts made via the Bluebell Railway Trust, and standing orders set up to provide a steady income to the project have now made over a third of the total available. Whilst this has provided funding for the present work, more is going to be needed to complete the project, and the best way in which you can help is by setting up a small, regular, standing order to the Bluebell Railway Trust under Gift Aid, since this enables the Trust to reclaim the basic rate tax you have paid, and (if you are a higher rate tax-payer) enables you to reclaim some tax as well.

Return to BRPS Home Page,

to the Timetable or to Special

Events

Atlantic Project - Background - Completion and launch - Next Projects: 'Normandy' and the Adams Radial Tank

Visitor Info. -

Museum -

Trust -

Catering -

Contacts -

What's New -

Projects -

Locos -

Carriages & Wagons -

Signals -

History -

Other -

Links -

Search -

FAQ

Why not become a BRPS Member? -

Get more involved as a Volunteer

Your ideal Film/TV location?

Photos and reports from Fred Bailey and Neville Watts.

Photos and reports from Fred Bailey and Neville Watts.

Page maintained by Richard Salmon

© Copyright BRPS. Privacy Policy

|