|

|

|

|

Locomotives - Operational Locos - Locos under overhaul - Locos on static display - Locos formerly based on the Bluebell Loco Roster - Loco Stock List - Loco Works News - Join the Loco Dept

Locomotive Works NewsOverhaul of SECR P-class 0-6-0T No.27

is available on the PROJECT 27 BlogSpot, on the Little Loco Group web site, and on Facebook May 2015 PROJECT 27 Restoration News A momentous event took place this month; the cylinders were removed from between the frames. After a few weeks taking out the 24 fitted bolts that held the cylinders securely in place, the gang were able to lift the cylinders from the frames. The cylinder block was placed on a pallet in the works yard next to the balance weight.

It is already possible to see that the cylinders will have to be replaced. This will entail constructing wooden patterns of each half of the block to enable a casting to be made so that the foundry can construct sand moulds in which new castings can be made. The Fenchurch Fund - Project 27 is currently discussing the best way to go about the manufacture of these.

The fragility of the block, and the effects of being open to the elements, can clearly be seen in the picture of the top of the block. The studs and nuts are severely corroded, but this is minor when you look at the hole that has been caused by the corrosive action of a build-up of smokebox ash and rainwater! The patterning on the rest of the top of the casting also indicates a vast amount of corrosion and consequent thinning of the steam passage walls. Whilst the bores look to be fairly undamaged, they are in reality less than ideal and almost certainly worn out of size and roundness. The valve faces have also been exposed to the elements and again are more than likely to be well out of tolerance.

A temporary stretcher has been constructed and put in place at the front of the frames to hold the frames in the correct relationship to one another. The original idea was to put the front balance weight back between the frames to act as the temporary stretcher until it was realised that by doing so, it would prevent the inspection of, and work on, that section of the inside faces of the frames! It was noticed that there is a small amount of corrosion at the top of the frames in the area of the cylinders, but nothing of too much consequence. This area will be built up with weld to its original thickness before primer and paint can be applied.

So, we have virtually finished phase 1 of the restoration, the stripping down to individual parts. Now the "less glamourous" part of the restoration begins! All of the removed parts will need to be thoroughly cleaned, primed and undercoat applied. The parts will also need to be meticulously labelled before being carefully stored until the time they are required to be finished and got ready to go back on the loco. It is envisaged that some of the items will be fully restored for display purposes at various exhibitions on and off the railway to give people an idea as to what a restoration consists of! If you would like to come on down and help on the restoration, working Parties are usually to be found working on the loco on most Saturdays. Please just come along and introduce yourself to us or E Mail us at thefenchurchfund@gmail.com for further information. For regular progress reports, please visit our blogspot page. April 2015 PROJECT 27 Restoration News Plenty of progress again this month, although much of it is not immediately visible! Both of the pistons have now been removed from the cylinder bores. To achieve this, the crossheads had to be removed from the piston rods by placing a wedge between the end of the piston rod and a bar placed in the holes which take the pins which locate the small end on the crosshead. A series of sudden downward pressure applications were made to the wedge to move the crosshead from the piston rod. Once the crossheads were removed, the pistons could be extracted from the front, sliding the piston rod through the rear cylinder cover. Finally the rear cylinder covers could be removed. This now leaves the cylinders empty and the cylinder block ready to be removed from between the frames.

During the month, the frames were transferred from the temporary wooden supports onto a set of frame stands kindly passed onto us by the Atlantic Project and our thanks go to them for this generous action. With the frames now on the stands, it has enabled us to level them both longitudinally and across the frames which will assist in the accuracy of future works to the frames, including the welding of new segments at the rear.

The right hand tank was prepared and painted during the month. This was done to form a display on Platform 1 at Sheffield Park to commemorate the 100 year anniversary of 27 going to France with the ROD. The tank was rubbed down and filled where necessary before being given a couple of coats of olive green and lettered as ROD 27. This is the condition it was in when it left Ashford Works destined to assist in the construction works in Boulogne.

The work being done on the steam reverser by Ben Dingley and Ian Ferguson is continuing on Thursday evenings, courtesy of Marlborough

School. The piston rod which supports the two pistons has now been completed and the fittings are being replaced onto it.

Attention has now turned to the cylinder cover which is broken and appears to be beyond repair. Ben has commenced the production of a pattern which will be used to cast a new part. This involves producing a replica of the cover in wood. This is then used to produce a sand mould into which the molten metal is poured to produce a new cover. COMMEMORATION OF 100 YEARS SINCE 27 WENT TO WAR On Saturday 25th of April, we remembered the part that 27 played during the First World War by having a commemoration day at Sheffield Park. The right hand tank has been placed outside the Bluebell shop in the livery of the ROD as we believe it looked at the time of embarkation. We cannot be 100% sure of the accuracy as there are no pictures or drawings in existence, that we are able to trace, but from contemporary descriptions, we believe we have got it about right. This was unveiled by Russell Pearce (Operations Director) and Graham Aitkin (Senior Station Master Sheffield Park).

The day was supported by the 10th Essex Regiment of re-enactors who made the day special. They provided a guard of honour for the

unveiling as well as recruiting "new volunteers" who took the King's (chocolate) shilling. They also provided drill demonstrations and

cameos every time the vintage train left Sheffield Park with Wives and Daughters seeing of their loved ones!

We launched a commemorative badge to mark the anniversary. This will be available for purchase on our sales stands for the next 18 months, or until they sell out! Matthew Cousins has produced two paintings to assist in the fund raising for the project, and were released at the event. The first is a depiction of 27 and 753, the two P tanks that were sent to France, on the dockyard at Boulogne, interest in this is quite high and on day 1 we sold 5 prints of the painting. The original is available for offers in the region of £180, the prints cost £15 and are available to order now. The second painting shows No. 27 in 4 of the liveries it has carried during its 105 year history, consisting of SECR Lined Green, ROD unlined Green, Southern Lined Green as A27 and early logo BR Black as 31027. These are also available to order. Working Parties are usually to be found working on the loco on most Saturdays. If you would like to join the band of brothers (and sisters) working on the loco please come along and introduce yourself to us, or E Mail us at thefenchurchfund@gmail.com for further information. For weekly progress reports, please visit our blogspot page. March 2015 PROJECT 27 Restoration News We have seen much progress this month, following the removal of the balance weight from between the front of the frames at the end of February.

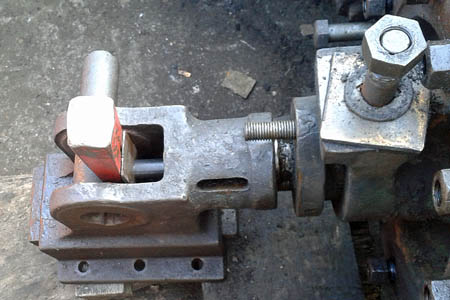

With the cylinder covers in place and the nuts still on the threads, our attention turned to removing the crosshead from the piston rod. This was a relatively straightforward process which was carried out by supporting the lower part of the crosshead upside down on packing, placing a bar within the casting butting up to the piston rod, and placing another bar put through the little end pin hole. A wedge was then placed between the two bars and downward pressure applied to force the two bars apart, and therefore loosening the grip of the crosshead on the piston rod. The crosshead was removed with this fairly simple technique and then put to one side for cleaning and storage. It is believed that this is the first time the crosshead has been off the piston rod for about 55 years when the loco went through an overhaul at Ashford Works, just before delivery to us. Once the crosshead was clear, it was a relatively easy operation to remove the cylinder cover, which needed to pass over the piston rod. This was put to one side for inspection, cleaning and possibly Non Destructive Testing. As the cylinder covers are subject to relatively high steam pressures the covers will need to be thoroughly checked and tested for any damage before any restoration work can be done on them. With the Cylinder cover off, it was then an easy task to remove the piston from the cylinders by sliding it forward and, using a hoist to support the weight, sliding it out of the bore. The pistons will be inspected and any remedial work carried out before storing until they are needed. When the pistons are reunited with the cylinders, they will have been thoroughly overhauled and new piston rings fitted. The left hand cylinder and piston was treated in a similar manner and proved no more difficult to deal with than the right hand cylinder. It has gradually become apparent over the course of the project to date, that it is 95% certain that we will need new set of cylinders

for 27. This is likely to prove quite costly and will involve a lot of work to create a pattern to allow a sand casting to be made.

Investigations are taking place to see if it would be viable to construct two sets of cylinders as it is thought that those on 178 may need

replacing in the fairly near future.

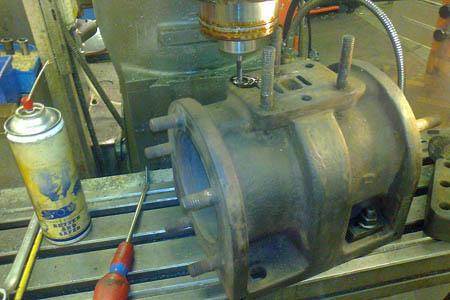

In addition to the work being done at Sheffield Park, Ben Dingley (AKA Essex Ben) is working on the steam reverser for 27 as a college machining project on Thursday evenings under the instruction of Ian Ferguson, who is a workshop volunteer at Sheffield Park. Between them, they have honed both cylinder bores, to remove years of surface rust and restore the roundness of the bores to within the original specification and tolerances.

An inlet port on the steam cylinder was found to be broken through and in need of replacement. The area was ground out and then welded up to slightly larger than required, by the Bluebell Railway's welder Paul Betts, before it was machined to down to its original shape and size.

The slide valve has been machined to restore the surface and remove some damage to the face. This was necessary to ensure the efficient

working of the steam reverser when it is returned to service. At the bottom of the valve body, a plug was specially made and inserted to

repair a previous working repair which had been in place for probably over 50 years and was deemed to be not fit for further use.

Following the manufacture of the piston rod, the pistons will be fitted. Further work on the overhaul will include overhauling the white metal bushes in the bearings at the ends of the piston rod before reassembly of the reverser can take place. Also, it appears that one piston cover may need to be replaced as this was cracked through and is probably beyond repair.

Working Parties are usually to be found working on the loco on most Saturdays. If you would like to join the band of brothers (and

sisters) working on the loco please come along and introduce yourself to us, or Email us

for further information.

We had a fairly successful day at the Wealden Railways Group Personal Model Railway show in Steyning on Saturday 21st of March, handing out many leaflets for PROJECT 27 and The Stepney Club together with plenty of Bluebell Timetables. We also sold plenty of preserves, tea cans and mugs, and even a baseball cap to one of the Railway's senior Drivers! We would like to record our thanks to The Wealden Railways Group for their kind support of our cause. The Wealden Railways Group's website can be found at: http://www.wealden.weebly.com. They are predominantly a communication group with a member's only website. An annual membership fee is available at a cost of £3-50.

SPECIAL EVENTS TO BENEFIT PROJECT 27 Special Days coming up include, on the 25th of April, a day to commemorate the 100th anniversary of the SECR sending No.27 to France as the first of the ROD locomotives. There will be a display of pictures, a parade by the 11th Essex Regiment re-enactors, the launch of a commemorative badge, the unveiling of a painting of 27 and 753 in the ROD livery they carried when they went to France and the unveiling of one of the tanks in ROD Livery. There is no charge for this event, but there will be plenty of opportunities to donate and spend your hard earned cash! We are also benefiting from a special train that is being organised as a test trip to assess the suitability of using Baxter on Passenger trains. This will happen on Sunday the 3rd of May with a fare of £18 per participant; this fare includes a meal in the Bessemer Arms and a return trip to East Grinstead. There is a choice of two departures to book on, the first will depart from Sheffield Park at 6pm with the meal being served upon arrival back at Sheffield Park, the second departure will be at 8:15pm with the meal being served before departure from Sheffield Park. Just a small amount of small print! Please remember that this is mainly a test train and if the crew and travelling inspectors have any reason to believe there may be a problem, there may be some adjustments to the timings and the possibly of terminating short of East Grinstead. Also, if Baxter is not available on the day a suitable substitute locomotive will be provided.

To book, please let us know which of the departures (6pm or 8.15pm) you would prefer and send a cheque (payable to The Bluebell Railway) for

the number of tickets you require to Project 27, C/O Millfield, Manor Road, Upper Beeding, West Sussex. BN44 3TJ. February 2015 PROJECT 27 Restoration News

The crossheads will need to be freed up on the slide bars before they can be removed for remedial work and storage. The slide bars will then need to be removed from their supports on the back of the cylinders and the motion bracket. Again, these will need to be thoroughly cleaned and any remedial work carried out before they are stored pending a final restoration just before they are refitted.

A temporary frame stretcher will be constructed to hold the frames steady whilst the cylinders are out of the frames. The cylinders

will need to be removed, split and inspected to confirm the condition they are in. However, it is not expected to be the best of news!

Working Parties are usually to be found working on the loco on most Saturdays. If you would like to join the band of brothers (and

sisters) working on the loco please come along and introduce yourself to us, or E Mail us at the usual address for further information.

January 2015 PROJECT 27 Restoration News Sunday 25th January 2015

The two connecting rods were removed at the same time. This involved rotating them around the axle, removing two nuts and applying a gentle downward persuasion to remove the tapered bolts. Whilst removing these it was found that the right hand connecting rod strap had a rather large crack in it. This was made worse by the removal process, but the original crack may well have rendered the strap unusable, so the additional damage should not be too much of a problem! It is believed that the right hand connecting rod may also need to be replaced owing to damage sustained at some time in the not too distant past.

There is also plenty of cleaning and painting of components previously removed from the loco happening which, although laborious and sometimes tedious, is a vital foundation for a long lasting working locomotive. The parts currently being cleaned are the guard irons, sand pipes and brake rigging. As the parts are cleaned they are labelled using small metal labels attached to them before storing ready for final painting later. We are in the process of producing a "priority list" to make sure the right parts are done in the right order!

We will be running "official" working parties once a month starting, hopefully, in March 2015. If you would like to join us please contact

us by E mail . You will need to be a member of the BRPS and either have attended, or be willing

to attend a short safety course organised by the Bluebell Railway (at no cost to yourself). You can also send an E Mail to the same address

if you would like to join the E mailing list for regular updates and information regarding our activities.

The wheels were placed in a position to have the axle boxes removed and stored prior to any remedial work that may need carrying out.

The connecting rods were also positioned ready to be removed from the crank axle and their condition assessed. It is believed that one

of these may need to be replaced due to previous damage. Once these jobs are done and the journals have been protected from the elements

the wheel sets will be given a superficial cleaning including the removal of flaking paint and "crud" before being sent for tyre turning

at the appropriate time.

The frames have been positioned so that the front balance weight and cylinders can be removed using a fork lift. This will allow the experts to carry out a detailed inspection of the frames and cylinders. The cylinders will need to be split to allow an inspection of the inside surfaces. This will give us the information we need to assess if we need to replace the entire block, or if it is feasible to repair it in some way. However, with recent experience on 178 it appears that maybe repair will not be our best option. The removal of the cylinders will also enable us to assess the condition of the inside surfaces of the frames. We know already that the rear third of the frames will need to be replaced, and there are a number of weld repairs visible on the middle section of the frames, what we don't know is what the front third of the frames are like. It is possible that there will be corrosion between the cylinders and frames and if this is the case there may be the need to replace the frame plates. The frame stretchers, horn guides and motion bracket all appear, at this stage, to be suitable for future use. Whatever is done to the locomotive, we are aiming to repair it to serve for up to 100 years before major parts need replacing again. The existing frames are now 105 years old and are, quite definitely, showing signs of their age.

Saturday 3rd January 2015

The working parties will be in cooperation with the 9F Club, who are keen to help the project. We will probably meet the week before

the 9F Club so that we can leave them suitable work to carry out during their work days.

We will be having a publicity and sales stand at the Wealden Railways Group model exhibition on the 21st of March in the Steyning Centre. This is predominantly an exhibition of members model railways and we are indebted to the Wealden Railways Group for allowing us to be with them. We will also be attending the Bluebell Railway Preservation Society AGM with a publicity and sales stand on the 16hth of May. We will also be running the usual AGM Bubbly raffle with tickets available on the night at £1 each. The Bluebell Railway will again be running the successful model railway weekend again this year and we will be doing our bit by providing a display of 4mm scale P tanks and terriers, as well as a few other Bluebell locos, together with a model railway in 009 giving a flavour of the trench railways of the First World War. In addition, we will be running a sales stand selling the usual items, and we try to have some second hand model items for sale, so, if you are looking for a good cause to donate those old model you have in the attic, please remember that PROJECT 27 can turn them into cash for the restoration of SECR No.27. To arrange pick up of items please contact us E mail. Thanks. August 2013 PROJECT 27 Restoration News

During a survey of the cylinders recently it appears that there may be a requirement for a replacement set to be cast. If a new set of cylinders is to be cast there are two methods that can be explored. Firstly there is the traditional method of constructing a wooden pattern that can be used to produce many castings, which is useful if there are any faults in the casting, but the production of a pattern is likely to be very expensive for one or two sets of cylinders. A cheaper method is the production of polystyrene patterns. These are only usable once as they are destroyed as the molten metal is poured into the mould. There is an article on page 38 of the May/June edition of "Heritage Railway", which describes the process and how the patterns are used.

There is a possibility, however, that the cylinders can be lined to extend the life of the casting, but a final decision cannot be made

until the cylinder block has been removed from the frames and stripped down. It is likely that this will not happen until the New Year

at the earliest.

PROJECT 27 Fundraising We now have a "Just Giving" page available to accept donations as well as the existing methods. Since launching this method of donation in early August, less than a month ago, we have received donations amounting to £100. We can also receive donations by cash or cheque, you can also add gift aid if you are able. PROJECT 27 Sales Stands and New Stock

In 2013, we attended the Brighton Model World exhibition (22nd to 24th February), the Burgess Hill Model Railway Club exhibition (11th May), the Bluebell Model Weekend in July, the Bluebell AGM, the Corby and District Model Railway Club Summer Exhibition and the Bluebell Vintage weekend, where we had a stand in the field at Horsted Keynes. These events were very lucrative for us, and useful to publicise both PROJECT 27, other funds around the railway and the railway as a whole. We have been invited to take a stand to the Leamington and Warwick Model Railway Society Exhibition at Stoneleigh Park next March, which will further help with publicity, both for us and the railway as a whole. The next big event for the fund raising to take place will be the Santa Season! We would appreciate any offers of help that may be forthcoming, I know that everyone is busy at that time of year, but even one day of your time would be of great use. Full training will be given! At these events, we will be selling the usual items including Tee Shirts, Fenchurch 140 mugs, Enamel tea cans and our new line, Red Engineman's Neckerchiefs. We will also have the Project 27 key rings and fridge magnets with us. Volunteering Opportunities with PROJECT27

If you would like to help us by volunteering on the sales and Information stands or with the restoration and care team, please contact

Clive Emsley by E Mail and he will contact you with information of how you can help.

You must be a member of the Bluebell Railway Preservation Society for insurance reasons.

December 2012  As of the middle of December, it appears that just about all of the components that can be removed from the frames prior to lifting have

been removed. It has also been discovered that both the left and right tanks are beyond economic and sensible repair and will need to be

replaced with new ones. These tanks will be designed and built to as close to the original pattern as feasibly possible based on modern

construction techniques and legislation.

As of the middle of December, it appears that just about all of the components that can be removed from the frames prior to lifting have

been removed. It has also been discovered that both the left and right tanks are beyond economic and sensible repair and will need to be

replaced with new ones. These tanks will be designed and built to as close to the original pattern as feasibly possible based on modern

construction techniques and legislation.

One of the condemned tanks has been cleaned up and is currently being painted into Southern Railway lined green and will have "Southern A 27" painted onto it. This is being done for display purposes such as open days and the like and to give an impression of what the loco might look like once restored.

It is probable that we will be using an offcut from the material left over from the cutting of the frame extensions used to convert the Class 2 2-6-0 into a 2-6-2T, for a new front buffer beam for 27. This makes economical sense and uses steel that is "spare". We are still waiting for date to be confirmed for a crane to lift the frames, we are also exploring the possibility of using other methods of lifting the frames from the wheels. Once the wheels are separated from the frames, there will be a noticeable change in the appearance of the frames and wheelsets. They will be able to be cleaned and a protective coat of paint applied and will greatly enhance the look of the loco.

The restoration team have been experiencing problems with the facilities in the Villas lately. There was a problem when the work bench

collapsed through rot and caused some damage to the outside wall of the building. This will necessitate a repair to the building and the

construction of a new heavy duty workbench. This will be done during the winter, but will hold up the restoration of smaller pieces of

the loco over the winter.

In 2013, we will be attending the Brighton Model World exhibition (22nd to 24th February), the Burgess Hill Model Railway Club exhibition (11th May), the Bluebell Model Weekend in July and of course the Bluebell AGM (18th May). There are probably other places we will be having a stand and these will be confirmed later. At these events, we will be selling the usual items including Tee Shirts, Fenchurch 140 mugs, and our new line, Enamel tea cans. We will also have the Fenchurch Fund key rings and fridge magnets with us.

Volunteering

My apologies to our readers, and Clive, for the delay in preparing this update for the web site - RAS.

July 2012  There has not been a huge amount to report in the last couple of months, partly due to other commitments for the Villas Gang, but mainly

due to the weather. This resulted in having to replace the roofing felt on the villas, which took the ingenuity and perseverance of both

Stuart and Matt. This is now complete and work is progressing on the loco once more.

There has not been a huge amount to report in the last couple of months, partly due to other commitments for the Villas Gang, but mainly

due to the weather. This resulted in having to replace the roofing felt on the villas, which took the ingenuity and perseverance of both

Stuart and Matt. This is now complete and work is progressing on the loco once more.

The front buffer beam, which was damaged in a shunting incident many years ago has been removed (seen in the photo on the right). An assessment will now be made as to the possibility of straightening it or replacing it during the restoration. It is thought more likely that it will be replaced with new steel. The removal of the front buffer beam has allowed us to remove the slide valves from the valve chest, which is located within the cylinder block, more easily. The photos below show the front of the frames, and the valve chest. The valves are now tagged and in store pending cleaning and preserving prior to any remedial works being carried out. A start has been made on the cleaning, red oxide painting and tagging of all of the brake rigging and other parts which have been removed from the loco before being stored. These will be worked on during periods that we cannot work on the loco outside and in the order they will be required for refitting. We are currently awaiting a crane to remove the frames from the wheelsets. This will have to be part of a planned days work of lifting for a hired in crane to make it financially viable. Once the frames have been removed from the wheels, they can be set up on stands to allow us to level the frames. We will also need to construct temporary accurately fitting stretchers to hold the frames to the correct spacing.

Once the frames have been set up it will be possible to remove the cylinders from the frames ready for work to commence on them. This

will also be the time to remove the frames at the rear of the loco and construct new replacement parts.

Alternatively the mugs will be available for sale, along with sets of postcards and vinyl OO scale transfers to rename you Hornby Terrier(s) at the Vintage Weekend (Aug 11-12) and at the Fenchurch 140 Open weekend (Sept 8th/9th) which is being organised by the Fenchurch Fund with the assistance of the Bluebell's Commercial and Operating Departments. Marmalade, and Beetroot Chutney, will also be available, as will many "Genuine Belgian" items! If you have some time on your hands and would like to become part of the restoration team please drop an Email to Stuart Marks for further information and practicalities. We are also looking for helpers on display and sales stands on and off the railway, no experience necessary, a sense of humour is required though! If you would like to be part of the fundraising team please contact Clive Emsley. March 2012  Clive Emsley's photo on the right, taken on 17 March 2012, shows the rear stretcher that has been built up with weld to its original

cross section. This is positioned just in front of the rear axle and behind the firebox.

Clive Emsley's photo on the right, taken on 17 March 2012, shows the rear stretcher that has been built up with weld to its original

cross section. This is positioned just in front of the rear axle and behind the firebox.

The last of the motion has now been removed from the locomotive and is in the process of being cleaned up and readied for protective paint and other processes prior to medium term storage. The front sandboxes are in the process of being removed prior to cleaning up and storage away from the weather. Currently these are held in place with temporary fixtures, the rivets having been cut out. The removal of these items will allow the front of the frames to be thoroughly inspected, cleaned and given a protective coat of paint. It has been found that the rear stretcher, below the footplate, was not as bad as originally thought and it has been built up with weld to close to the original section. There is some corrosion on the main frames in a similar area that it is hoped can be treated in a similar way. The stretcher has been given a coat of protective paint and looks good.

The front buffer beam, which was cracked and bent in a shunting incident a number of years ago, will need replacement, although it is

thought that the drag box behind it will only need minor repair, obviously when dismantling of this part of the loco takes place more

definite information will become available

The rear of the frames will need to be removed from just behind the rear foot steps and replaced with new sections. This will pose no great problems as this technique has been used in the past with 263 and more recently with the BR Class 2 tank. This will be done once funds are available.

As was stated in the last report, the locomotive has been prepared for lifting from the wheels. Unfortunately the preparation work for the

new staff accommodation above the workshop has prevented any crane movements in the works yard, so this is currently on hold. Once the

wheels have been removed from the frames, plans can be made to have the wheels sent away to have the tyres and journals turned, ready for

the loco frames to be put back onto the wheels and become a rolling chassis.

Fund raising, via the Fenchurch Fund which is supporting the restoration of No.27, is coordinated by Clive Emsley, Millfield, Manor Road, Upper Beeding, Steyning, West Sussex BN44 3TJ. New fund raising forms are now available. They include sections for one off donations, with or without Gift Aid and for setting up Standing orders, again with or without Gift Aid. These can be supplied from any of our stands at various Bluebell Functions or by post or Email. Thank you for your support. 10 February 2012

The restoration began when the loco was dismantled in 1978 for a "quick" overhaul, but, as was so often the case at the time, this was found to be beyond the skills of the basic workshop capability we had back then, so the restoration stalled. The restoration of No.27 to working condition has recently restarted following a delay of nearly 30 years. The work on the locomotive is being undertaken by the Villas Gang and other volunteers, supported by the fund raising efforts of the 'Fenchurch Fund'. Major work is required on the boiler and frames of the locomotive, as well as some significant mechanical renewal and replacement of plate work, including the tanks. The work that have been carried out recently includes the removal of all of the motion and valve gear from between the frames. These parts have been cleaned up, ready for repair and renovation of the bearings, before being stored. The bunker has been removed from the frames of the loco and set aside to allow a new bunker to be constructed using the original as a pattern. During the removal of the sandboxes it has been found that there is some significant corrosion to the front part, as well as the rear, of the frames which will need to be replaced. Temporary frame stretchers have been manufactured and fitted in readiness for the cutting out of the rust from the frames, and replacement with new material. The existing tanks are also set aside either to be repaired or to be used as patterns for the fabrication of new ones. The locomotive has been prepared for lifting which will be done as part of the next visit of a crane, potentially some time in February. This will allow work to be carried out on the frames, the axle boxes and the wheel sets.

is available on the PROJECT 27 BlogSpot, on the Little Loco Group web site, and on Facebook

Go to the web page for this loco

Return to BRPS Home Page, to the Timetable or to Special Events Locos Intro - Operational Locos - Locos under overhaul - Locos on static display - Locos formerly based on the Bluebell Loco Roster - Loco Stock List - Loco Works News - Join the Loco Dept Visitor Info. - Museum - Trust - Catering - Contacts - What's New - Projects - Locos - Carriages & Wagons - Signals - History - Other - Links - Search - FAQ Why not become a BRPS Member? - Get more involved as a Volunteer Last updated 02 June 2015 by Nick Beck and 28 August 2019 byRichard Salmon. Reformatted 17 April 2022 © Copyright BRPS. Privacy Policy |