Carriage & Wagon Dept -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

C&W News

SR Coach Group - Goods Division -

Operation Undercover -

Technical -

Join us

Carriage & Wagon Works News

London, Brighton & South Coast Railway

6-wheel Fruit/Milk Van No. 270 of 1908

20 August 2015

LB&SCR Fruit/Milk Van No. 270, following completion of restoration.

Jim Hewett

Whilst the superb restoration of the body is complete, there remained two challenges to be solved to enable the van to run - the brake gear didn't fit around the new (fatter) axles, and so has had to be redesigned and remanufactured. The second challenge is taking longer, and this is with the vehicles springs, which in spite of two attempts have so far resisted a satisfactory overhaul.

October 2011

To the casual observer there might not seem to be much progress since the last update and there have been setbacks.

After fitting the roof in summer 2010 it was left without fitting the canvas as that needed to wait until the van could be brought inside the main workshop. However, around Christmas time it was noticed that wood had taken up moisture and swelled considerably, pulling out a lot of the fitting screws whilst doing so. At that time it was decided to do nothing until the warmer weather came when it was hoped it would largely return to its original shape. What actually happened was that the boards stayed the same shape but shrank leaving gaps. It was fairly obvious that the roof would have to be re-boarded with new wood and that the work would have to be done inside the main workshop where the conditions were more stable. The canvas covering would have to be fitted and painted before it could be exposed to extreme conditions again. A similar problem occurred with the floor boards but they have now been permanently fixed.

Warping in roof boards (13 January 2011) - John Knight rubbing down the paintwork (31 March 2011)

Right: Inside but with the roof removed again (16 June 2011)

Right: Inside but with the roof removed again (16 June 2011)

The move inside was made in June and the roof stripped immediately. New wood was ordered and it was cut so that it had a natural tendency to curl the same way as the roof. The attachment method was changed so that bigger screws could be inserted downwards into the iron roof hoops giving a much stronger fixing. By mid October the boarding was completed and it was awaiting the gutters to go on before the canvas was fitted.

A lot of effort went in to getting the sides and ends ready for the top coats of paint. There were many layers of brushing filler and undercoat and it all had to be rubbed down. Most is now ready for the gloss coats although that will not be done just yet.

The work on restoring doors has now been on-going for nearly two years with only two sets anywhere near complete. Some of the work is now being done by volunteers who are not normally part of the project.

The other major work undertaken during 2011 is making the mouldings. These are quite intricate and time consuming to make; a small mistake can render the whole piece un-useable. To give added strength where they might otherwise break across the grain pieces of the same wood are being let in on the back with the grain running at right angles to strengthen them (see picture). About three-quarters of the mouldings are now complete.

New mouldings (17 March 2011) - Back of a moulding with strengthening pieces let in across the grain (23 June 2011)

The van in its present location in the works (15 June 2011 - John Knight) - Most of the mouldings trial fitted to the north west corner section (14 July 2011) - Roof-end moulding fitted at South end (12 August 2011)

Top of the roof, showing the new fixing method and the cover plate over the wiring for the lights (22 September 2011) - The roof boarding finished, awaiting gutters and canvas (20 Oct 2011)

Report and all photos, (except as indicated), from Jim Hewett. Apologies for the delay in presenting this update, which was submitted in October 2011 but then overlooked.

November 2010

Since the last update the immediate first task was to fit all the outer plywood panelling. The first photo above show that by the end of February the east side panelling was well under way. This took most of the first half of 2010.

Following this the mouldings for the ends were made and trial fitted, and the second photo, taken on 31 October, shows the south end with the mouldings and lamp brackets trial fitted. They are being removed for painting. Producing more mouldings is on-going.

At the same time another team were repairing doors which is a long and difficult task as some were in a very bad condition. The photo on the right shows an example of one of the old doors, very little of which can be re-used.

Some others doors from a similar van were found in store and these are still being assessed. Some of these will be used as they are in better condition than the originals. So far only two door carcasses have been completed but parts have been made for others.

The first photo below shows Peter Chaston shaping one of the new door stiles with a router. In the second, John Knight is screwing together a repair to one of the doors.

In July the roof boarding was started and was finished a few weeks later. The wooden gutters have been made and some have been trial fitted.

The photos below show the first of the roof boards in place at the end of July, and that by September the boarding of the roof was finished.

The springs were sent away earlier in the year to be re-tensioned as the first attempt resulted in the van riding too high. When these were returned in the middle of the year everything was in place to fit the new wheel sets (photo above) and the springs (seen being fitted in the second photo above, awaiting the rolling of the new wheels underneath) at the same time. This involved the use of the electric carriage jacks which are in use most days. Eventually a slot was found on Sunday October 31st and the job was done although it took all day. This also allowed photographs to be taken of the whole vehicle as this is impossible whilst it is in the polytunnel.

The final photos show the re-wheeled vehicle on 31st October, and a test run in the yard. Two of the bearings ran warm so will need attention.

The next few months should see the brake gear assembled. The outer paint will have to be rubbed right down before the new paint can be applied.

There are still lots of other things to be done. Much of the internal boarding can be used again and this has to be cleaned up along with numerous other pieces of wood. There is a lot more work to do on the doors.

With luck it might be finished by the end of 2011.

(Report and photos thanks to Jim Hewett)

31 December 2009

The last 6 months have seen the base frame for the body assembled on the underframe and this included glueing together the two side bottom rails and completing the sub-floor structure (as seen in the photos above, taken in July 2009). The individual sections are glued together and then bolts added, countersunk into the top surface with nuts and washers underneath.

The next task (later in July, seen in the first photo below) was to loose-fit the floor boards to give a platform to work on to assemble the body frame.

In addition, the "greenhouse" up to this point only had doors on the end large enough to enable the underframe to be shunted in and out. With the impending erection of the body, the end had to be modified to create a larger pair of doors, as seen below.

There was some delay after this as the body framework needed some more attention and several trail assemblies before it could finally be fitted to the base. Once all the pieces of the jigsaw fitted, as seen in the photo on the right mastic was applied to joints (in place of the white lead paste that would originally have been used) and the assembly finally put together for one last time.

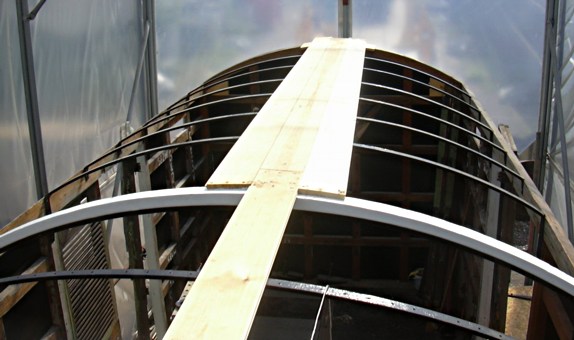

Next the roof hoops were fitted, each having to be adjusted individually to give a straight roof line. The four knee brackets which hold the sides to the base were fitted and adjusted to make the sides vertical. Brackets were then fitted between the door and corner posts and the bottom rails.

The photos below, taken on 10th December show most of the hoops aligned. Some however cannot be fixed until after the internal timber cladding has been fitted.

Finally, as seen on the left and below, on Christmas Eve the first of the outer panels were fitted. These are cut from ply, and painted before fitting. We're pleased to find that the 8x4 sheets of ply are a slightly larger metric equivalent, which enables much more economical use of material with less waste, since the panels are just the wrong sizes to come out of sheets that are exactly 8' x 4'.

The other photo is of the new wheel sets and the old one which was used as a pattern. The new ones are Southern Railway disc wheels which have been pressed onto new axles, machined to suit the LBSCR bearings and axle-boxes.

(Report and photos thanks to Jim Hewett)

June 2009

Following the repairs to the underframe detailed in the previous report, the main effort was switched to the body of the van. During the summer of 2008 the base frame for the body was repaired and renewed as necessary. All the outside rails were renewed, the side rails each having to be fabricated from four pieces of timber which will be glued and bolted together when fitted to the underframe. There was a trial assembly of the base frame towards the end of summer 2008 (photo above left). The second photo above shows how the bottom side rails are bolted together.

Work then commenced on the repair of all the body frame sections and that continued until mid 2009. In the meantime the new bottom rails had been prepared to accept the body frame sections. By May 2009 enough work had been done to trial assemble the whole body framework on the workshop floor (photo below) but this produced a further list of jobs to be done before the body was ready for assembly on the underframe. This occupied the team up to the end of June.

Interestingly, during restoration it was noticed that there were numbers stamped into the door pillars (second photo below) which probably refer to folding shelves as there is evidence of hinges being fitted close by. It is hoped to restore this feature.

New wheels and axles are required and on 24 June 2009 the underframe was lifted using the new electric jacks to remove the centre wheelset which was sent away as a pattern for the axles. This was the first use of the jacks, but their use on heavier loads must await construction of the proper jacking pads alongside the track between the pit and 270's plastic home.

Some work has been done to restore the vacuum brakes and parts have been acquired to add air brakes also.

(Report and photos thanks to Jim Hewett)

Spring 2008

Hopefully updates on this project will now become more frequent. Jim Hewett has provided the photo above, which shows the underframe now repaired and re-wheeled. To fill in the story since the last report, illustrated in the photos below, the van body has been dismantled, with careful notes being made of all positions of internal fittings and shadows left by ones removed. Whilst this design was designated as a Milk/Fruit van, the positions and size of shelves indicates that this one was probably dedicated to fruit traffic.

Hopefully updates on this project will now become more frequent. Jim Hewett has provided the photo above, which shows the underframe now repaired and re-wheeled. To fill in the story since the last report, illustrated in the photos below, the van body has been dismantled, with careful notes being made of all positions of internal fittings and shadows left by ones removed. Whilst this design was designated as a Milk/Fruit van, the positions and size of shelves indicates that this one was probably dedicated to fruit traffic.

The underframe was then stripped down, and repairs made to the ends of the timber solebars, and both headstocks replaced. The most expensive part so far has been replacement of the steel flitch-plates along the outside of the underframe, requiring many holes drilled in precise places. The inner flitch plates, shorter sections, were in better condition and have been repaired as necessary and refitted.

Since the photo above was taken in March, the

progress has been on two fronts; one team is refitting and adapting the

brakes for a dual vacuum/air system whilst another team is preparing timber

for the base of the body.

Above left: The van in the course of being dismantled (March 2007)

Above right: The underframe after removal of the body, about to be lifted from its wheels (July 2007) (Photos: Jim Hewett)

Above left: The van's underframe - this photo shows the generally good condition of the underframe timbers (May 2007)

Above right: The solebars stripped of all brake gear, with the wheels removed (July 2007)

Below left: The new ends grafted onto the solebars (Nov 2007)

Below right: The new steel flitch plates drilled and ready for cleaning, painting and fitting (Jan 2008) (Photos: Dave Clarke)

January 2007

Most of the covering is now on the temporary building, such that the main dismantling can now proceed. One task undertaken before the covering was installed was the unthreading of the 14-ft length of the buffers and the drawgear, as can be seen lying alongside the carriage in the second photo above.

Most of the covering is now on the temporary building, such that the main dismantling can now proceed. One task undertaken before the covering was installed was the unthreading of the 14-ft length of the buffers and the drawgear, as can be seen lying alongside the carriage in the second photo above.

The photos below show that the doors and external panelling have been removed, and that much of the internal planking has also been numbered up, and some of that removed.

Work started 29 October 2006

The photo on the right by Dave Clarke, shows the building part-way through erection, in August 2006, with Van No. 270 beneath its tarpaulin.

Over the last few months the framework of the temporary building which is to house the van during its overhaul has been completed. It still awaits its external covering, but work has started on the van itself, which is still under its tarpaulin.

The Thursday Gang have removed the external doors and cleared the interior. As much evidence about the van's history as possible is being gathered whilst dismantling of the interior starts.

Funding for the project is provided thanks to a bequest left to the Bluebell Railway Trust for that specific purpose.

Return to the web page for this van.

Return to BRPS Home Page,

to the Timetable or to Special

Events

Carriages & Wagons -

Intro -

Development -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

Carriage Fleet Review -

Join us

C&W Works News - SR Coach Group - Goods Division -

Operation Undercover -

Carriage Shop -

Technical Pages

Visitor Info. -

Museum -

Trust -

Catering -

Contacts -

What's New -

Projects -

Locos -

Carriages & Wagons -

Signals -

History -

Other -

Links -

Search -

FAQ

Why not become a BRPS Member? -

Get more involved as a Volunteer

Your ideal Film/TV location?

Last updated 13 January 2012 and 26 December 2021 by Richard Salmon

Last updated 13 January 2012 and 26 December 2021 by Richard Salmon

© Copyright BRPS. Privacy Policy

|